Color-coated aluminum coil is a kind of high-performance aluminum coil m

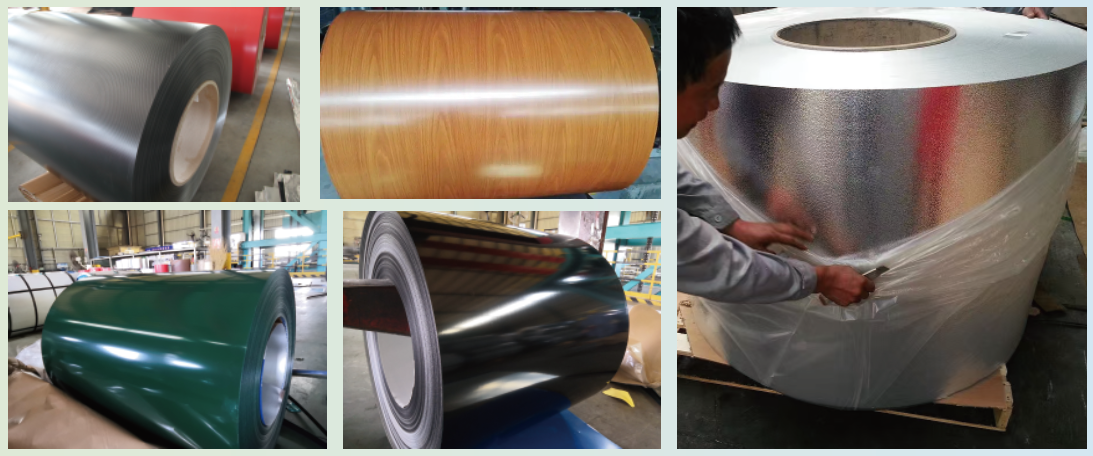

Color-coated aluminum coil is a kind of high-performance aluminum coil manufactured by advanced surface treatment technology, Substrate (AA1100, AA3003, AA5052) series aluminum alloy, thickness range of 0.2mm to 3.0mm, width of up to 1600mm, the surface is chromed and coated with PVDF (polyvinylidene fluoride, polyvinylidene fluoride, polyvinylidene fluoride, polyvinylidene fluoride, polyvinylidene fluoride, polyvinylidene fluoride, polyvinylidene fluoride, polyvinylidene fluoride. For outdoor use) or PE (polyester, mainly used indoors) paint.

Core production step

1.Substrate Pretreatment

● Degreasing & Cleaning

Use alkaline or neutral degreaser (pH 9-11) to remove oil and oxide layer on the surface of aluminum plate (residual oil ≤20mg/m², in accordance with EN 12206 standard)

● Chromating Treatment

Produces chromium-free or chromium-containing conversion film (Cr³ + content < 0.1mg/m² is environmentally friendly, traditional chromified film thickness 0.3-1.5μm), enhances coating adhesion and corrosion resistance (in accordance with ASTM B449)

● Rinsing & Drying

Rinse and dry with pure water to ensure that no impurities remain on the surface

2.Multi-layer Coating

● Primer

Epoxy or polyurethane primer (thickness 5-10μm) for improved coating bonding (adhesion tested to ASTM D3359 Class 5B)

● Topcoat

PVDF (Polyvinylidene fluoride) : contains more than 70% PVDF resin (such as Kynar® 500), 20-30μm thickness, UV resistance, chemical resistance, suitable for harsh outdoor environments.

PE (Polyester) : Economical polyester coating (thickness 15-20μm), rich color, suitable for indoor or mild climate conditions.

● Back Paint

Optional protective acrylic coating (thickness 5-8μm) to prevent oxidation on the back of the aluminum plate

3.High-temperature Curing

The coating is cured in a **220-250℃** high temperature baking oven (PVDF should be ≥230℃) to form a dense and durable film layer (hardness ≥2H, ASTM D3363).

Product advantage

Strong corrosion resistance:Aluminum substrate natural oxide film + coating double protection, increase the corrosion resistance of the product

Light weight and high strength:Density 2.7g/cm³, thickness 0.15-3.0mm, tensile strength 150-300MPa

Strong plasticity:The product is easy to bend and press

Application scenario

Curtain Walls:Supertall buildings (such as PVDF coating used in Burj Khalifa outer envelope in Dubai)

Transportation:High-speed rail body (AA5052 substrate +PVDF coating, 30% weight reduction)

Electronics:5G base station shell (PE coating, electromagnetic shielding + anti-corrosion)

Interior:Ceiling (matte PE coating, Fire rating A2)

Product data

|

Substrate |

AA1100 (Pure Al)/AA3003 (Mn Alloy)/AA5052 (Mg Alloy) |

|

Thickness |

0.15-3.0mm |

|

Tensile Strength |

AA3003: 110-285MPa AA5052: 170-305MPa |

|

Coating Type |

PVDF (Outdoor)/PE (Indoor) |

|

Coating Thickness |

PVDF: 20-30μm PE: 15-20μm |

|

Salt Spray |

PVDF≥2000h (No Corrosion) PE≥1000h |

|

Weathering |

PVDF: QUV 4000h ΔE≤2.0 PE: QUV 2000h ΔE≤3.0 |

|

Eco-standard |

RoHS Compliant, Chromium-Free Conversion Coating |