Color coated steel coil is a kind of high performance metal coil treated by prec

Color coated steel coil is a kind of high performance metal coil treated by precision coating process. Its base material is cold-rolled steel or galvanized steel, the thickness range is usually 0.13mm to 1.2mm, and the width can reach 1250mm to meet different engineering needs.

Core production step

1.Substrate Pretreatment

● Degreasing

By alkaline solution or electrolytic cleaning, completely remove the oil on the surface of the steel plate (residual oil ≤50mg/m²) to ensure the adhesion of the coating.

● Phosphating Treatment

Compact phosphate conversion film (film weight 1.5-3.0g/m²) for enhanced rust protection (according to ISO 9717)

● Passivation

Some processes increase the chromate passivation layer (Cr³ + 10mg/m² content) for improved corrosion resistance

2.Multi-layer Coating

● Primer

Epoxy based coating, thickness 5-10μm, provides substrate rust protection and adhesion (scratch test Class 0, ASTM D3359)

● Topcoat

Polyester, silicone modified polyester or fluorocarbon resin, thickness 5-45μm, color and weather resistance (QUV 2000 hours light retention ≥80%)

● Back Paint

Epoxy or acrylic coating, thickness 5-15μm, protects the back of the steel plate from environmental erosion.

3.High-temperature Curing

The coating is cured for 20-30 seconds in a continuous baking oven at 200-240℃ to form a cross-linked network structure (pencil hardness ≥H, ASTM D3363).

Product advantage

1.Weather fastness

This product has high UV resistance, fade resistance, design service life of 10-35 years (depending on the selection of materials, layers)

2.Light weight

The thickness of this product is 0.13-1.2mm, the density is 7.85g/cm³, which can effectively reduce the building load

3.Aesthetic

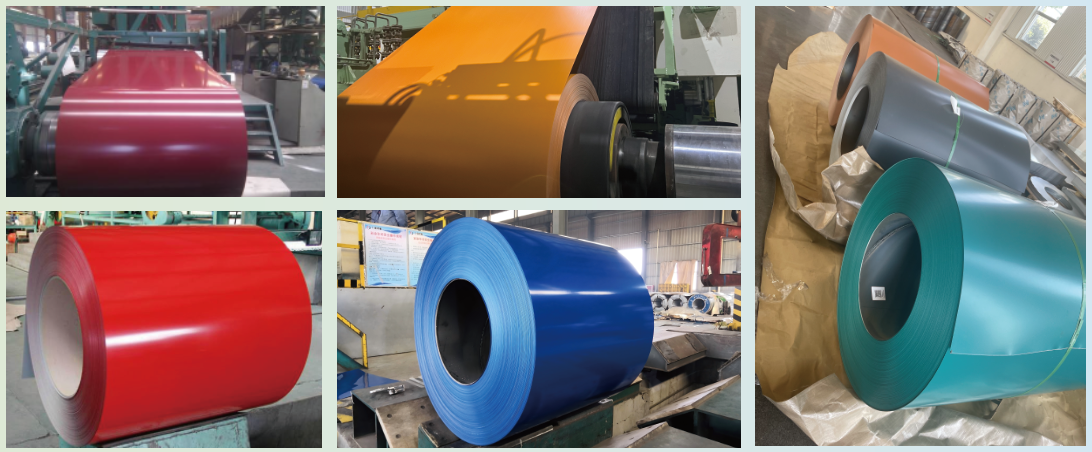

This product offers a variety of colors (RAL color card standard) and imitation wood grain, stone grain effect

4.Substrate diversity

Available in hot dip galvanized (GI) or aluminum-plated zinc (GL) steel plates, this product provides additional corrosion protection (3-5 times increased corrosion resistance of the zinc layer)

5.Resin Type

Polyester: Economical and versatile, suitable for indoor environments.

Silicon-modified polyester: Enhanced temperature resistance and UV resistance, suitable for outdoor construction.

Fluorocarbon: Super weather resistance (35 years + life), used in landmark buildings.

Application scenario

Construction field:roof, wall, sandwich board (such as factory, airport, stadium)

Home appliances:refrigerator, washing machine, air conditioning shell

Total assets:indoor ceiling, partition

Product data

Substrate | Cold-rolled Steel (SPCC)/Galvanized Steel (SGCC, DX51D) |

Thickness | 0.13-1.2mm |

Zinc Coating | Dual-side Zinc Coating 20-275g/m²(Z06-Z275) |

Coating | Front Side 10-55μm, Back Side 5-15μm |

Salt Spray | ≥500 Hours (Red Rust Area <5%) |

Bending | T-bend ≤2T (No Cracking) |

Weathering | Xenon Arc 2000h, ΔE≤3.0 |

Eco-standard | Compliant with RoHS & REACH(Heavy Metal-Free) |