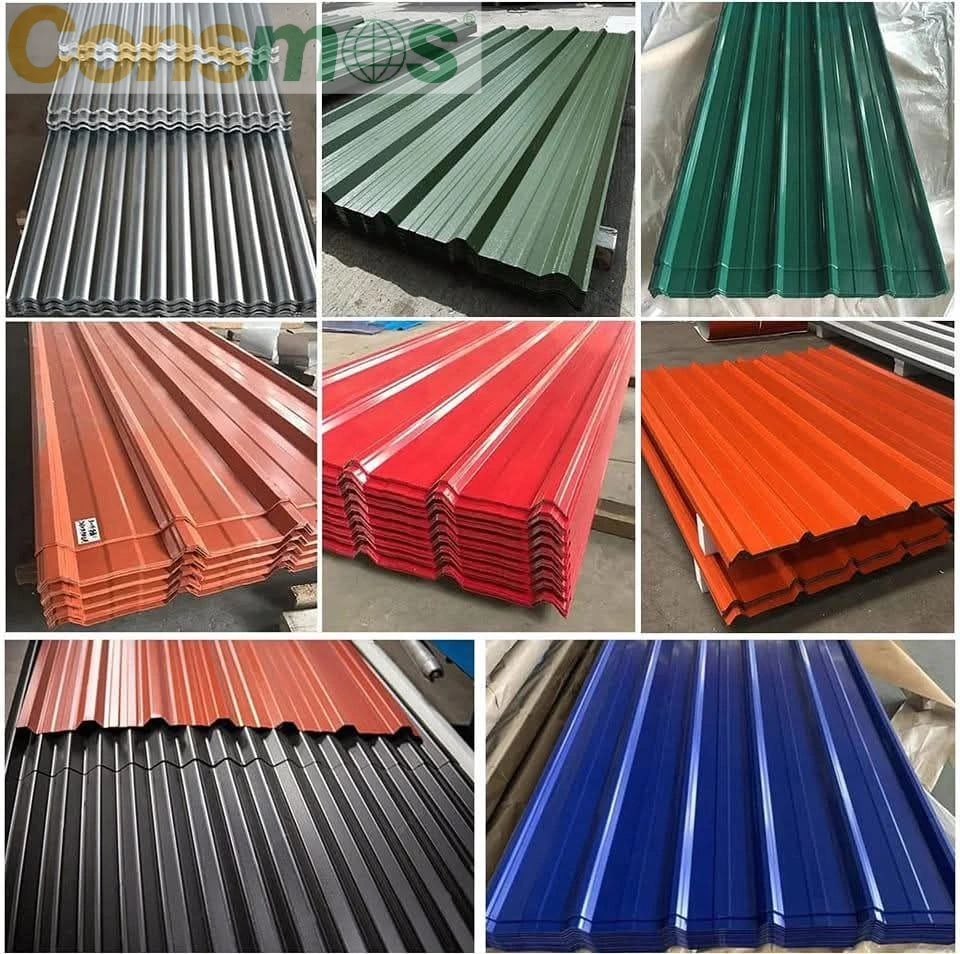

Consmos Metal, a leading building materials supplier, provides high-performance Color Steel Tiles, durable, efficient, and aesthetic , they are ideal for modern construction.

What are Color Steel Tiles?

Color steel tiles are metal roofing/wall panels made from coated galvanized or galvalume steel, roll-formed into structural profiles. They are valued for high strength, corrosion resistance, and versatility in industrial, agricultural, and prefab steel buildings.

I. Core Product Classifications

By Substrate:

Hot-dip Galvanized (GI): Zinc-coated. Strong rust resistance, cost-effective. Ideal for humid environments.

Hot-dip Aluminized Zinc (AZ): Superior corrosion & oxidation resistance. Longer lifespan; recommended for coastal/high-salt areas.

Cold-Rolled (CR): Budget-friendly, coating-dependent protection. Best for dry indoor or temporary use; avoid long-term outdoor exposure.

2. By Wave Shape (Profile):

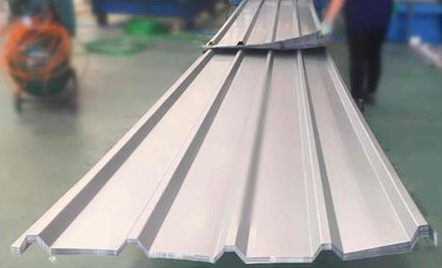

Standing Seam: High profile, interlocking seams. Excellent sealing, wind, and snow load resistance. Ideal for large-span factory roofs.

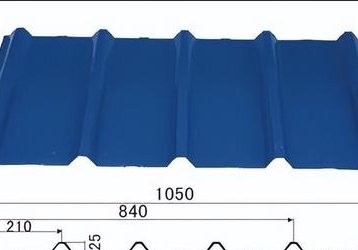

Roof Sheeting (e.g., Type 840/900): Balanced profile height for easy installation and cost-effectiveness. Versatile for both roofing and wall applications.

Wall Sheeting (e.g., Type 950/980): Low-profile, flatter surface designed primarily for aesthetic and protective wall cladding.

Tile-Imitation Profile: Mimics traditional clay or slate tiles. Combines durability with decorative appeal, perfect for scenic spots and residential projects.

3. By Coating Type:

PE: Basic, cost-effective, 5-8 yrs, inland.

SMP: Better UV/flexibility, 8-12 yrs, moderate corrosion.

HDP: High durability, 10-15 yrs, harsh outdoor.

PVDF: Premium, >15-20 yrs, coastal/industrial.

II. Key Performance & Selection Parameters

Thickness: 0.3–0.8mm (strength).

Coating: Front 20–30μm, back 10–15μm.

Zinc mass: e.g., Z100–Z275 (rust protection).

Cover width: Effective coverage per sheet.

Weathering: PVDF > HDP > SMP > PE.

Fire: Class A (steel only).

III. Advantages and Considerations

Advantages:

Lightweight (10–14kg/m²), fast install, colors, waterproof, rustproof, recyclable.

Practical Considerations:

Needs insulation layer; coating scratches must be repaired; wind resistance depends on installation.

IV. Common Application Scenarios

Industrial: Factories, warehouses.

Commercial: Markets, canopies, prefab houses.

Temporary: Site offices, shelters.

Decorative: Facades, signage.

V. Procurement and Usage Guidance

Industrial: Factories, warehouses.

Commercial: Markets, canopies, prefab houses.

Temporary: Site offices, shelters.

Decorative: Facades, signage.

#BuildingSolutions #MetalSheeting #Rooftop #ConstructionIndustry #Supplier #Manufacturer