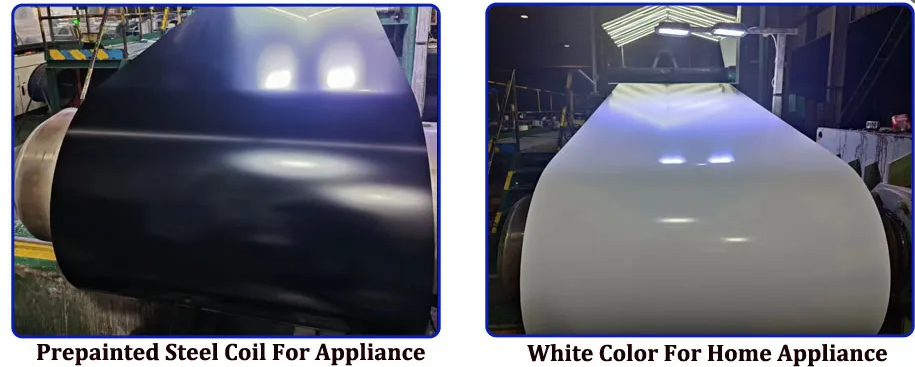

Pre-painted steel coil for home appliance

CONSMOS GROUP

Introduction

Pre-painted steel coil for home appliance is with good processability and decorative properties. Pre coated steel sheet is widely used as front panels, side panels, back panels and inner panels of household appliances. You can find it in refrigerators, microwave ovens, washing machines, air conditioners, water heaters, display cabinets, vending machines, DVDs, computers, etc. Generally,pre-painted steel sheet uses hot-dip galvanized, galvalume (alu-zinc)and cold rolled steel as the substrate. In our factory, we have pre-painted steel and PVC/PET coated steel sheets to choose fom. Welcome to contact us for more detail information.

Specifications of color coated steel for home appliance

Item | Home appliance panels |

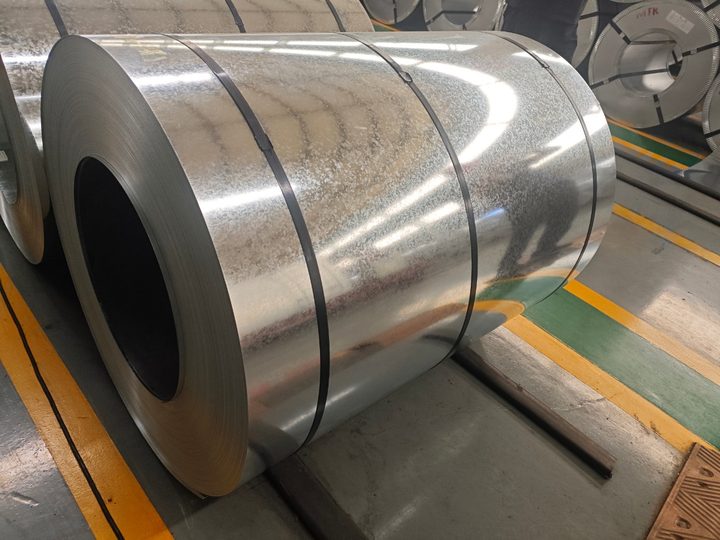

Substrate | Cold rolled steel,galvanized steel,galvalume steel |

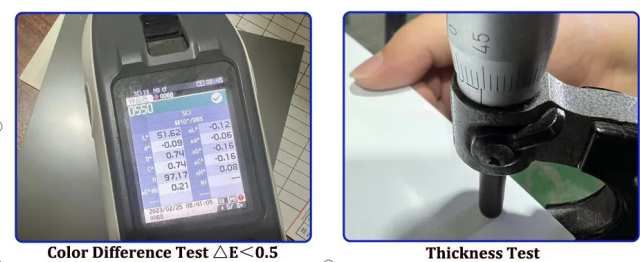

Thickness | 0.3mm-1.2mm |

Width | 600-1250mm |

Popular colors | white, black, grey, silver, silver grey, beige, etc. |

Coating method | Double-coating and double-baking process |

Coating thickness | Top paint: 15-25 μm Back paint: 5 μm as per request |

Lamination | 30-50 μm |

T-bend test | ≤2T |

Color difference | △E<0.5 |

E-cupping test | 6mm |

Mek test | More than 100 times |

Impact test | No cracking and peeling(50kg/cm) |

Painting company | PPG/ Valspar /becker/ kcc /nippon |

Pre-painted Steel Sheet Features

►Great processing performance;

►Excellent chemical resistance;

►High scratch resistance;

►Delicate decorative performance, etc.

Pre-painted Steel Sheet Uses

1. Pre-painted Galvanized Steel Coil is widely used in refrigerators, microwave ovens, bread makers, washing machines, air conditioners, DVDs, water heaters, televisions, and other household appliances;

2. Also, coated sheet metal is popular in freezers, display cabinets, vending machines, and other commercial appliances.

Types of Home Appliance Panels

1.Pre-painted Metal for Home Appliance

Due to its rich colors and high production efficiency, pre-painted steel is widely used for exterior walls, roofing, interior decoration, windows, doors, etc. Currently, it is also popular in transportation and home appliances.

However, prepainted coils for home appliances uses special top paintings, which makes the surface glossy. The front panel uses polymer linear oil-free polyester resin coating and the back panel uses modified epoxy painting.

Also, you can find conductive and matte PPGI sheets on the market. Relatively speaking, the color coated sheet is not as smooth as the PVC/PET coated steel sheet. So pre painted galvanized coils are mainly used as side panels but is not very suitable for the front panel of high-end household appliances.

2.PVC/PET Coated Steel for Home Appliance

PVC/PET coated color steel has a beautiful appearance, excellent processability, and superior resistance to corrosion and scratch. Besides, painted steel sheet can show different effects from low light to high light, pearlescent effects, and exquisite patterns. Therefore, colored galvanized sheet metal is widely used in refrigerators, washing machines, and other household appliances.

Choosing Color-coated Steel for Home Appliance

As mentioned, the base material can be cold-rolled steel sheets, hot-dip galvanized sheets, galvalume sheets etc. Among them, cold-rolled sheets are mainly used for exterior sheets of refrigerators and washing machines. In contrast, hot rolled steel plate is mainly used for shells of air conditioner compressors. Hot-dip galvanized sheets are mainly used in air conditioner outdoor units and back panels of refrigerators. In comparison, fingerprint-resistant sheets are preferred by high-end household appliances such as computers, VCDs, microwave ovens, washing machines, air conditioners, etc. Generally, the pre painted metal sheet used in refrigerators is 0.7mm and 0.8mm in thickness. At the same time, that for microwave ovens is 0.5mm and 0.8mm.

♦According to Regions

Moreover, different regions have different choices for color-coated steel for home appliances. In Japan and South Korea, the side panels of refrigerators often use high-gloss single-color panels. While in North America and Europe, low-gloss panel, like the embossed panel is more popular because they can not only enhance the strength of the pre painted sheet metal during the embossing process but also cover the surface defects of the base metal.

♦According to Applications

Due to the indoor use of home appliances, there is no high requirement for weather resistance and aging performance. However, it requires higher boiling water resistance and acid and alkali resistance. In addition to its significant decorative effect, painted steel sheets also need to meet some specific use requirements, such as non-toxicity, high processability of microwave oven shells, the resistance to detergents of washing machine shells, the scratch resistance of refrigerator side panels, etc. At the same time, in order to prevent scratches during stamping, the protective film needs to be retained until the end user removes it. If the protective film is released before leaving the factory, pre painted coil steel requires 60 units of adhesive force. While if the protective film is removed by end users, it requires 180 units of adhesive force.

Difference Between Pre-painted Steel for Home Appliance and Construction

Actually, there is no essential difference between the color-coated steel for home appliances and construction. But home appliance panels have higher requirements for substrates and coatings. Below let's review their differences in coatings, base metal, and applications.

1. Paintings

In construction uses, the primer is epoxy resin paint or and the topcoat is polyester paint or other coatings with the same performance. While for home appliance uses, the primer is polyester paint and the topcoat is polyester paint or other paint with the same performance.

2. Applications

The color coated steel for home appliances is mainly suitable for white goods, such as freezer, washing machines, air conditioners, water heaters, microwave ovens, TV back panels, electrical boxes, stereos, etc. In construction, colored steel sheets are mainly used for roofing sheets, partition walls, curtain walls, ceilings, security doors, windows, fencing panels, etc.

3.Base Metal

Generally speaking, painted coil steel for construction requires higher strength and better corrosion resistance. This is because it is usually a part of the stress-bearing structure and is used in a complex outdoor environment. While color-coated steel for home appliances uses normal-strength steel sheets. As for base metal, hot-dip galvanized steel and galvalume sheets are commonly used for construction, while electro-galvanized sheets and cold rolled steel are generally used for home appliances.

Home Appliance PPGI Steel Sheet Processing Requirements

When processing home appliance PPGI steel sheet into desired home appliance housing shape, please pay attention to the following requirements.

1. Environmental requirement

Before processing home appliance galvanized steel sheet, please make sure the surface of die and processing equipment is clean.

2. Mould exactness

High exactness die should be used. The die, which directly contacts with the PPGI steel sheet's coating material,is recommended to bechrome plated and finely polished.

3. Accuracy

The die should come with correct amount of clearance between the punch and die, so as to ensure accurate end product size and shape. The clearance can be adjusted according to the total thickness of substrate, paint coating, and 70% thickness of protection membrane.

4. Lubrication and heating up processing

Lubricating the die and protection membrane of the home appliance PPGI steel sheet, and heating up the steel sheet, can greatly improve the product surface quality and entire processing effect.

As one of the professional prepainted steel coils manufacturers, we employ a complete imported coating line and adopt double-coating and double-baking process. Our pre painted coils are widely used in refrigerators, freezers, washing machines, air conditioners, microwave ovens, water heaters, televisions, etc. In addition to common colours, pearlescent and metallic products are also available. We offer color coated steel with different base materials, finishes, and specifications.

Welcome to contact us for more details!